We continue our look at performance slot cars with a review of an NSR model…

After last month’s brief overview (here), I’ll now be focusing on one model each from NSR, Policar and Slot.it. The three cars I’ve chosen are – I think – good introductions to the brands. They are fun to drive on home tracks and their performance shouldn’t be too challenging for those of us more used to standard Scalextric cars. And they are a superb way of experiencing non-magnet racing.

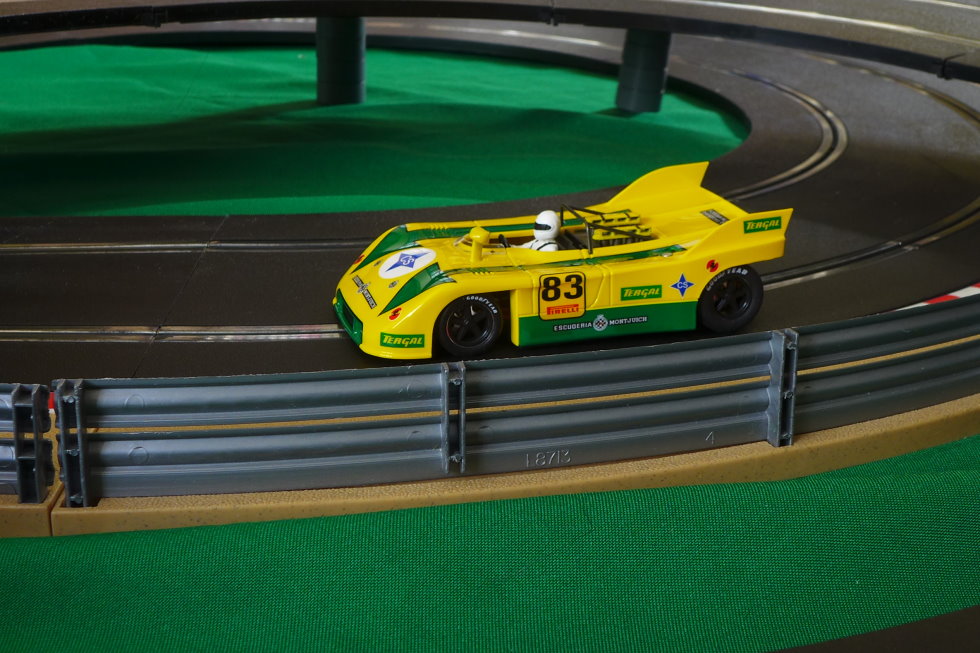

The NSR car I’ve chosen is the relatively new Porsche 908/3 from their ‘Classic’ sports car range. The livery is of the Escuderia Montjuich car that won the 1973 European Hillclimb Championship in the hands of Juan Alfonso Fernández.

It is available from the Jadlam website here: https://www.jadlamracingmodels.com/nsr-porsche-908-3-escuderia-montjuich-champion-montana-1973-1-32-0129sw/

Who Are NSR?

NSR are a small Italian company based in Salerno, near Naples. Their factory opened in 2010 and it’s where NSR cars are designed, manufactured and assembled. Salvatore Noviello founded NSR to provide parts to slot car racers. NSR has been behind 13 slot car world champions and 40 Italian champions from 1997 to 2019, including Salvatore and his son Andrea. The first NSR model available to the public was the Mosler MT900R, which remains the ultimate performance slot car. All NSR models are designed to be competitive out of the box and are equipped with high quality components as standard. Their GT, Classic, Formula One and Rally Slot cars are all front-runners at local clubs – and in national and international competitions. The retail prices are high – twice that of a Scalextric car – but NSR fans will tell you they are worth every penny (and don’t forget the Jadlam price match!). Although Salvatore sadly passed away eight years ago, the company continues his vision, driven by a young and enthusiastic team.

The Real Porsche 908/3

The little 908/3 was almost unbeatable on the twisty tracks of the Targa Florio and the Nürburgring Nordschleife, helping Porsche to win the International Championship of Makes in 1970 and 1971. The story of the 908/3 began when the legendary 5-litre Porsche 917k replaced the 908 coupé. Porsche kept the 908 moniker and produced a new ultra-light 3-litre car, based on the 909 Bergspyder hillclimb car. Utilising specialist components, a lightened aluminium spaceframe and a fibreglass body, the 908/3 weighed in at just 545kg, whilst the engine pumped out over 360 bhp. That was a very impressive power-to-weight ratio back then. Thirteen examples of the 908/3 were built and several continued racing successfully through to the late 70s.

One of these cars was the 908/3 owned by the Escuderia Montjuich Team – a group of young, rich and well-connected Spaniards who were desperate to break out of the isolation of the Franco era. Their green and yellow Tergal-sponsored cars became a fixture in European motorsport during the early 1970s. One of their number, Juan Alfonso Fernández, became an icon of the European hillclimb scene, winning the championship in 1973 – driving this Porsche 908/3 – and also the following year with an Osella-Abarth.

The NSR Model

NSR unveiled their first Porsche 908/3 model in February 2018. The cute little car looked a perfect slot racer in every way – short, low, wide and with simple bodywork. Pitted against the other NSR Classic range cars, it was immediately the pick on the bunch.

The first liveries had the 1970-style body – without the tail fins – and featured two Targa Florio collectors’ twin-packs and the Nürburgring winner. The 1971 body was first released in April 2019 with another Escuderia Montjuich livery (from Le Mans 1972) and a twin-pack of the very tasty 1971 Martini-liveried Nürburgring cars (available here). My 1973 Escuderia Montjuich hillclimb car came out in April 2020.

The car looks stunning its box. And the packaging has two important pieces of information – “World Champion” and “100% made in Italy” – which certainly makes it stand out. Inside, there’s a small card which says “This model has been finished manually”. The message is clear – this is a car made by hand by world champions. That is the NSR philosophy and they are proud of it.

The decoration of the car is very sharp and has a perfectly-applied clear coat which is nice and shiny. Given this model is primarily designed and built for track performance, I am more than happy with the detailing parts in and around the cockpit. Having said that, the driver’s overalls and helmet are plain white (Fernández wasn’t The Stig) and his legs are amputated at the knees – plus the rear gearbox detail doesn’t cover up much. Nonetheless, the overall look of the car is great – it exudes the lightweight, high-performance ethos of the real Porsche 908/3.

The question with performance slot cars is always whether the model has been stretched – especially if it’s wider than it should be – to give an ‘out-of-scale’ and/or ‘out-of-proportion’ model for enhanced on-track characteristics. Looking up the dimensions of the real 908/3, the verdict is the NSR model is about 7% bigger all round, making it an accurate 1:30 scale model. I’m happy with that.

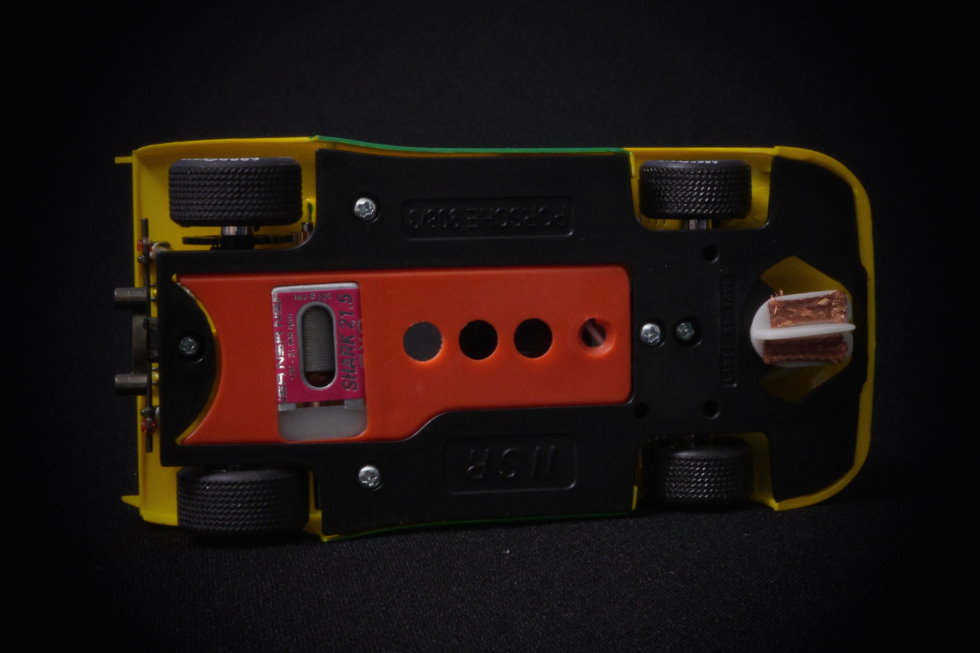

Removed from its plinth, I immediately noticed the lightness of the body and a superb body ‘float’ straight from the factory. I could also see the wheels and tyres – aluminium hubs back and front, fitted with accurate plastic inserts and grippy treaded tyres printed with ‘Goodyear’ logos. Turning the car over, there’s a two-part chassis with the motor pod moulded in red plastic and the motor positioned in a very slightly angled sidewinder orientation.

The Mechanical Stuff

Remembering how good that body float was, I carefully removed the two body screws – one front, one back – to look inside. The body really was light, tipping my scales at 13.8g. The layout of the chassis appears simple, but there’s plenty going on.

The first thing I noticed is the floating movement and satisfying ‘rattle’ of the body is replicated between the chassis and motor pod. The pod is attached to the chassis at three separate points – one at the front and one either side of the motor. This is the characteristic NSR layout. However, the screws are attached into separate ‘cups’ – which means the rigid motor pod floats beautifully. This movement isolates the motor and driven wheels from the rest of the car, improving power delivery and handling. These mounting points can be fitted with the NSR sprung suspension system that replaces the screws and cups. Soft, medium and hard springs are available. Other chassis and motor pod options include a choice of ‘hardness’ for both. This can be useful to dial in car to various track types, but the combination of black (medium) chassis and red (extra hard) motor pod is an ideal starting point and most racers stick with these.

Just in front of the motor is a big round magnet. In the car, it gives 45g of downforce on my DIY magnet gauge. However, because it’s quite narrow, that magnetic effect will only act when the car is driving in a straight line. In other words – lots of downforce (and reduced speed) on the straight and none if the rear steps out at all in the corners. That doesn’t make sense. But having a traction magnet in an NSR car doesn’t make sense – these performance cars are designed to run without artificial downforce. I’ll give it a few laps to see what it’s like and then remove it.

What else? The white guide flag turns smoothly and is self-centering thanks to the tension of the motor wires. The white guide won’t trigger laps with ARC powerbases, so is best replaced with a black Slot.it CH06 guide (here) if you use ARC. The pick-up braids are wired directly to the motor and there’s no attempt to offer a space to fit a digital chip. It wouldn’t be difficult to solder one in, but it clearly isn’t a consideration for NSR. I always recommend fitting performance cars with the Slot.it SP15B chip (here) to run on Scalextric digital systems.

The front axle is loose and floppy. Ideally, this needs to be stabilised and set to the desired height for your track (usually, just touching the track surface) – and four grub screws are included in the box for this purpose. You’ll need an NSR 0.05″ hex screwdriver (here) to fit these grub screws. It’s a really useful tool to have as the NSR wheels and gears are also fitted with the same grub screws. An alternative is the Gaugemaster GM592 Slot Car Tool Kit (here) which contains four screwdrivers – including one each for NSR and Slot.it / Policar grub screws – and a gear puller/press for changing brass pinion gears on performance cars. Not as good quality as the NSR tools, but much cheaper.

Perfectly-round lightweight aluminium wheels are fitted on all four corners, the rear wheels being the NSR Air System version. The wheels are secured to the axle using a grub screw. The tyres are genuine NSR racing compounds – Supergrips on the back and low grip on the front. As is standard with the Classic range, the tyres have a moulded tread pattern. It’s usually a good idea to glue NSR tyres to the wheels for racing. I’ll use them as they are in our test. NSR offer three different tyre compounds – Supergrip, Ultragrip amd Extreme. Supergrips are an excellent all-round racing tyre, although the softer Ultragrips are slightly more suited to Scalextric Sport track. The Extreme are essentially qualifying tyres – they won’t last very long!

At the back of the car, the gear mesh is super-smooth and has been set up perfectly at the factory. The high quality axle is held in the motor pod by machined brass bushings – a world away from the loose plastic Scalextric set-up. The NSR Shark motor used in the Classic range has the same layout and dimensions as a Scalextric motor, but there are differences. Firstly, you can see inside. The holes in the can help cool the motor, but also risk dirt and debris getting in and clogging up or damaging the moving parts. Covering the bottom opening with tape is not a bad idea – and giving the motor a good puff of air from time to time is good maintenance.

The motor is rated at 21,900 rpm at 12 volts – compared to around 18-20k for a Scalextric motor. However, the performance difference is mostly in the torque – the mechanical force that turns the gear and the wheels and also gives a braking effect. The torque of the NSR motor is calculated at 164 gram-centimetres (gcm), compared to around 100gcm for a standard Scalextric motor. This gives an overall power rating of just over 9 watts for the NSR (almost identical to the Slot.it motor we’ll be looking at) – and 5 to 5.5 watts for the Scalextric motor. That’s a big difference. To deal with this extra torque, the motor can be screwed tight to the motor pod – one screw is fitted at the factory. More powerful ‘long-can’ motors are used in the anglewinger and in-line motor pods of the NSR GT, F1 and Rally models. These are even further away from the characteristics of a Scalextric motor, which was one reason I picked a sidewinder ‘Classic’ model.

The gears are an 11-tooth brass pinion on the motor shaft and a 32-tooth aluminium crown gear on the rear axle. Both are designed to be strong and light. This ratio is different to the 11:36 fitted to a Scalextric sidewinder car. The NSR gear ratio will give a faster top speed, but the torque of the NSR motor will still give excellent acceleration and braking. Different ratios are possible with pinions having 10, 11, 12 and 13 teeth, plus sidewinder gears with 30, 31, 32, 33, 34, 35, 36 and 37 teeth. More teeth on the pinion typically gives more top speed and less acceleration. More teeth on the big sidewinder gear gives better acceleration and braking. The 11:32 ratio is a good all-rounder and should give a super-smooth ride.

It’s worth saying that this range of gears is specific to the NSR sidewinder motor pod – NSR in-line and anglewinder gears are different. The diameters of the gears are also specific to the NSR pod and are not easily interchangeable with other brands, such as Slot.it. The diameter of the NSR sidewinder pinion is 6.75mm and the big gear 17.5mm. A range of NSR plastic sidewinder gears has recently been developed in the same sizes.

Okay, that’s a pretty thorough look around the Porsche! One final thing to say is that NSR have an ongoing program to improve the parts on all their cars – even the oldest models like the Mosler. This keeps all the cars in NSR’s limited range up-to-date and competitive. You’ll see the term EVO next to many of the components – especially the motors, chassis and motor pods – this indicates the ‘evolution’ number. The Mosler chassis has been through several evolutions and the latest cars have the EVO5 chassis. Earlier versions can be updated – the latest EVO components are sold separately.

Before I get the car ready for the track, it’s worth mentioning the fabulous resources on the NSR website (http://www.nsrslot.it/). Each model has its own page with the specification and optional tune-up parts listed. You can then cross-reference to buy them on the Jadlam website. There’s also a pdf ‘Guide for Easy Set-up & Tuning’ on the download page and plans for a series of how-to videos for the ‘NSR World Champion’ YouTube channel. If you want to see one of the NSR factory team working on a well-used NSR Mercedes GT3 car, there’s a great video on the YouTube channel here.

Preparation

As you can see from the description of the ‘mechanical stuff’, almost all the hard work of race-tuning the car was done at the NSR factory. Although the background knowledge from the Scalextric Tuning series is useful to appreciate the features of the car, there’s not too much to do…

Unlike a Scalextric car, the moving parts of the NSR Porsche have not been smeared in grease. I have added a small drop of bronze bearing oil to the rear axle bearings, plus the bearings at each end of the motor. I’ve also placed a dab of grease on the gears and rolled the wheels to get that grease into all the teeth of the big sidewinder gear.

I’d rather not have the front axle flopping around, so I’ll set the height of the axle using the grub screws included in the box. It’s not too hard. I place the car on a flat piece of track (or a set-up plate) and let the tyres sit on the surface. I then insert a pair of grub screws into the top holes of the front axle support. I gently screw these down until they just touch the axle – and then back off half a turn. With top height set, I then turn the chassis over and insert the other pair of grub screws into the holes in the chassis under the axle. Again, I want them to just touch the axle – so it locks tight – and then I back the screw off one turn. This should give a free-spinning, level axle – with the tyres just touching the track surface – and just a tiny amount of vertical movement. With the NSR axle configuration, it’s enough just to fit the bottom screws – but I like to do both.

I am also going to reduce the side-to-side ‘slop’ of the front axle. I could insert an NSR spacer to fill the gap, but I will simply loosen the grub screw on one wheel, push the wheel in so there’s only a 0.5mm gap and then re-tighted the screw. I want the axle to spin freely, but with minimal side-to-side movement.

I also noticed one of the motor cables was a bit wild and rubbing on the front axle, so I have taped that to the motor to keep it under control.

The final preparation is to lift and spread the ends of the braids slightly. This will improve the electrical connection with the rails on my Scalextric Sport track.

Track Performance

Finally I got to give the little Porsche a run-out on my SL6 test track. Its first laps were witnessed by a family member who commented “Wow, that’s smooth!”

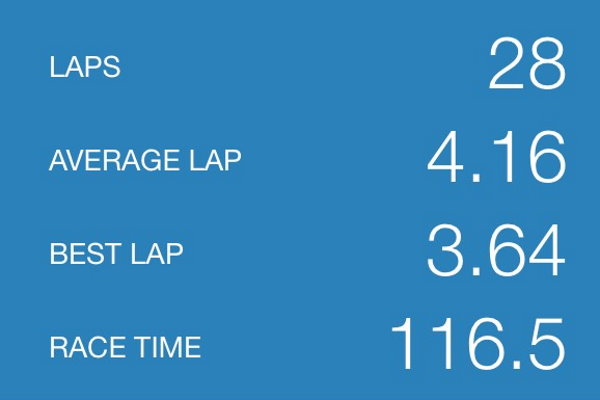

It was very smooth with the magnet in place – and very quick. The car was beautifully planted, but the rear does tend to break free – probably because of that narrow magnet. And when the car spins out, the outside rear tyre slips off the wheel slightly, which is enough to bring the car to a standstill. I wanted to time the car using the parts installed at the factory, so used the LapTracker app rather than swap the guide for a black one to use ARC. The app timed a 2-minute run and the Porsche completed 28 laps and clocked a best time of 3.64 seconds. Most of the laps were sub-4 seconds, apart from the penultimate one when the tyre slipped on the rim. That took 10 seconds to fix, which would have been enough for another couple of laps. So if you want a car that immediately smashes your lap record, get an NSR and run it with the magnet. However, that might be the only time my NSR 908/3 is run that way…

I took the Porsche to my workbench, removed the magnet and added a dab of glue (Bob Smith Industries IC-2000 Tire Glue) with a cocktail to fix the very edge of each rear tyre to the wheel. As with most things, less is more – and that glue really does make a mess if you use too much. Simply roll the tyre back from the rim, work a very thin layer of glue on the wheel and then roll the tyre back. Having let the glue set for ten minutes, it was back to the track for some ‘non-mag’ action – exactly what the car was designed for. I knew I wouldn’t be able to push anywhere near as hard as with a magnet fitted, but I did hope the tight track and standard ARC controllers wouldn’t stifle the potential of the NSR Porsche.

What I noticed immediately is that the ARC controller was a bit too ‘on/off’ – I wasn’t able to pull the trigger very hard at all. I turned on the ARC app and the default ‘throttle curve’ setting – Profile A – really softened the power so I could have some fun with the car. These settings only work when the app is launched – Profile A is the softest and ideal for non-magnet driving. It is a very different driving experience without magnets and it took me a while to get into a rhythm after having driven magnet cars all day. The back of the Porsche was using all the track, plus the borders – I had to remember to be particularly careful where there were no borders, but that was okay.

The joy of running without magnets is that you are in complete control of the car. With magnets, I am concentrating fully on not pushing beyond the limit of grip – otherwise the car is tumbling into the scenery. Without the magnets, a well set-up car can go beyond the limit and you’re still in control – the challenge then is to find a balance between speed and grip that gets you round the lap as quickly as possible. Big slides through the corners and tank-slapping down the straights looks superb and is great fun, but the neater the line, the quicker the lap. Because NSR design and set up their cars for non-magnet racing, they drive superbly from the moment you pop out the magnet. Scalextric cars take a lot of work.

I knew those earlier times for the Porsche 908/3 were going to well out of reach without the magnet fitted – but by how much? Once I had a good rhythm, I timed a two minute run – the LapTracker app on my phone and the ARC app on my tablet to access the Profile A throttle curve. With one small spin, the Porsche did 22 laps and a best lap of 5.24 seconds – but that doesn’t tell the whole story. On the small and twisty track, the Porsche never stretched its legs – it was always a bit sideways. Enormous fun though! On a larger track with wider radius curves, it’ll be more in its element. As I test these performance cars – and set-up up a few Scalextric cars for non-mag running – I’ll continue with the SL6 track, but maybe I need a ‘non-mag’ track design too. Something like the SL9 layout (https://www.jadlamracingmodels.com/scalextric-digital-c1413-bundle-sl9-arc-pro-jadlamracing-layout-with-4-cars/) would be ideal.

In conclusion… Despite the less-than-ideal track layout for the non-magnet NSR Classic Porsche, I have fallen in love with this car. I know I’m going to get lots of use out of it over plenty of years – at home and at clubs. I can spend time methodically tuning it, spend money upgrading components and – after a lot of hard racing – I can easily replace parts that get worn out. There’s a local club were I can race this car competitively and there’s another club a bit further afield that I enjoy visiting. Every year or two, NSR organise a UK Championship with one day for NSR GT3 models and a second day of Classic racing. My Porsche 908/3 will be ideal for that. All things considered, I can more than justify the cost of this NSR performance model for the use and enjoyment I will get from it. If it was an impulse buy with no long-term plans, I’m not so sure.

NSR Porsche 908/3 ‘Escuderia Montjuich’ Data Sheet

Catalogue code: NSR0129SW

Buy it here: https://www.jadlamracingmodels.com/nsr-porsche-908-3-escuderia-montjuich-champion-montana-1973-1-32-0129sw/

Range: NSR Classic – 1/32 scale, high detail 1960s & 70s sports cars

Released: April 2020

Spares included: bag containing 4 spare grub screws for front axle set-up

Lights: None

Motor: NSR Shark Evo 21.9k rpm ‘short-can’ – sidewinder orientation.

Gear ratio: 11:32

Length: 124mm

Wheelbase: 76mm

Rear axle width: 61mm

Height: 24mm

Weight: 66g (body 13.8g)

Andy’s downforce gauge: 45g magnetic downforce